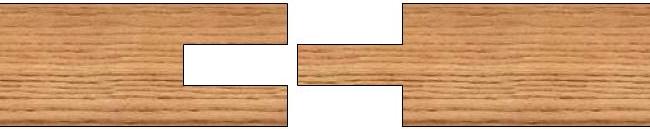

Figure 1 - Through tenon joint

A through tenon joint is stronger than a butt joint and lap joint, because the area that can be glued together is almost twice as much as either the butt or lap joint. To create a through tenon joint, a third of the material is removed from both sides of the piece of wood that will make the tenon - the male end and a third of the wood is removed from the center of the piece of wood that will accept the tenon - the female end, as shown in Figure 2.

Figure 2 - Through tenon construction

The through tenon joint is often used on frames and in order to join two lengths of wood together, end to end. Another major advantage of the through tenon joint over a butt or lap joint is that the joint is such that a twisting motion will not break the joint apart. This is not the case with butt or lap joints. A twisting motion can break either a butt or lap joint.

The strength of the through tenon joint can be increased by using nails, screws or dowels through the joint.

The through tenon joint is not commonly used because the creation of the tenon and the notch in the second piece of wood requires a lot of time and effort, in order for the joint to fit properly. It is an excellent joint choice for outdoor gates and other types of frames that require extra joint strength.

It is very similar in construction to a tongue and groove type joint which is used on sheets of wood.

The through tenon joint can be made using a router mounted in a router table, as shown in Figure 3, to make the female end or by using a dado saw blade

, as shown in Figure 4, in a table saw.