There are three variations of a rabbet joint.

- The basic rabbet joint where one piece of lumber is notched to accept a second piece of lumber, as shown in Figure 1.

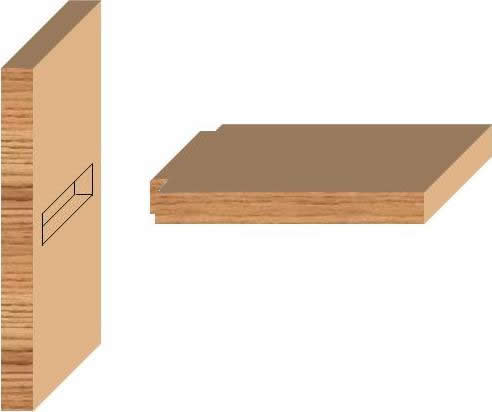

- The half rabbet joint where the both pieces of lumber are machined to fit into one another, as shown in Figure 2. Half rabbet joints are commonly used at the ends of lumber when making boxes or when fitting the top and bottom shelves to bookcases and cabinets.

- The stopped rabbet joint or as it is sometimes termed the blind rabbet joint, where the dado is not extended the full length of the board, as shown in Figure 3.

Figure 1 - Basic rabbet joint

Figure 2 - Half rabbet joint

Figure 3 - Blind rabbet joint prior to assembly

From the end view, it does not appear that a rabbet has been made in the lumber, as shown in Figure 4.

Figure 4 - Blind rabbet joint after assembly

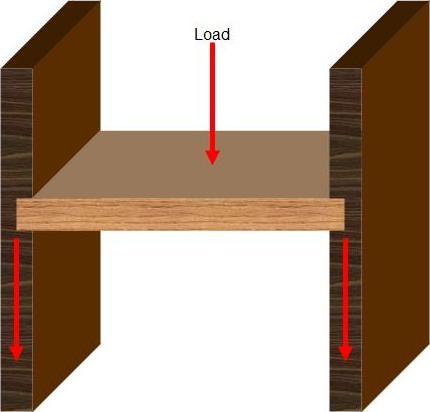

When a rabbet joint is used with vertical and horizontal pieces, such as a bookcase, you get a mechanical transfer of the weight from the horizontal to the vertical pieces, as shown in Figure 5.

Figure 5 - Rabbet joint load

The depth of the rabbet joint is usually half of the thickness of the lumber that the dado is made in although there is no hard and fast rule regarding depth. However, unless there is a very compelling reason the dado should never be more than half the thickness of the lumber and not less than a third of the thickness of the lumber.

Rabbet joints can be strengthened and reinforced by the addition of nails or screws through the mating pieces of lumber.

Rabbet joints are easy to make using a dado saw blade, as shown in Figure 6, in a table saw or a router

, as shown in Figure 7.